Cansda Machining

For any questions about our services you can reach out :info@cansdamachining.com

Discover the Power of CANSDA Machining to Optimize Your Time and Budget

Get a CNC quote in less than 2 hours for your custom metal or plastic part. You’ll get your quick-turn prototype or production part in as soon as three days!

-

60+ Materials Available

-

800000+ Unique Parts Produced

-

Parts as fast as 3 business days

-

12 years of industry experience

Have a project you'd like to talk about?

60+ Materials Available

800000+

Unique Parts Produced

Available in 57 Countries

2000+companines served

Why Choose Us for Custom CNC Machining

OEM Custom Machining Components from China: an ISO 9001-Certified company producing high quality machined components based on your designs and specifications,No limits on order size - we can scale with you from one-off prototypes to millions of production parts,let's work together to solve your CNC machining problems Now.

Save your Money &Time

Up to 20% lower raw material costs contributed by bulk order needs and stable supply guaranteed by professional manufacturing process, make it possible for our lower price. we guarantee the price you receive is the one that single-handly goods.

Obtain your quote within an hour

Pricing, lead times, and design feedback for manufacturing are only a click away, not days. Instant quotes simplify data science by allowing you to quickly determine the best price and lead time options for your project.

Full Support &Service

We offer a reliable 45-day after-sales service and quality assurance.

If you’re not satisfied with your order, we act swiftly, resolving the issue within three business

days without requiring any product returns, Save your time.

Strict Quality Control

Quality control from design to delivery:To ensure our parts always meet the CANSDA Standard, we have in-house quality control (QC) systems, Every custom part gets checked by our QC teams

On-Demand Manufacturing Service

CNC Milling Service

Using cutting tools or multi-point milling cutters, CNC milling removes materials from the workpiece to make items with a flat surface.

-

3, 4, 5-Aixs CNC Milling services.

-

tight tolerance up to +/-0.02mm (±0.0008 in.)

-

Delivery time 5 business days

CNC Turning Service

CNC Turning parts are made from a variety of materials, each with its own unique set of properties that make it ideal for specific applications.

-

Tolerances: ±0.125mm (±0.005″)

-

Max part size: 200 x 80 x 100 cm

-

Delivery time 4 business days

How to work with us?

if you're looking for a CNC machining service that offers efficiency, accuracy, and reliability - look no further than! We have advanced processing abilities including anodizing, low-volume pricing, and tighter tolerances. we are your one-stop service for machined parts. with fabrication catered to your project's requirements.

let us work together to solve your CNC machining problems for increased business success!

Experienced Machined Parts Supplier Since 2012

High-Precision CNC Machining Services to Meet Your Needs

-

CANSDA has a dedicated quality control team that ensures each piece we manufacture meets your standards. From the material selection process to the final inspection, we maintain strict quality control measures to guarantee your satisfaction.

-

100% inspection before shipment. all parts inspected using hand metrology, CMM or laser scanners

Experienced CNC Machining Team to Safeguard Your Projects

-

24-Hour Engineering Assistance, We have a specialized team of quality control engineers and support professionals. They can assist you with any of your manufacturing questions and are here to help you with your order from start to finish.

-

The engineers at CANSDA are dedicated professionals with more than 7 years of experience in the machining field, and they are available round-the-clock to meet your needs.

Surface Finishing

-

For CNC machined parts that improve aesthetic appeal, remove surface imperfections, and offer more durability, select from more than ten finishing options. Surface Treatment:

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc.

Our Quality Promise

-

we can provide Inspection reports for every order

-

All CNC-machined parts inspected using hand metrology, CMM, or laser scanners

-

All orders are highly vetted and managed, with 100% inspection before shipment.

-

ISO 9001 certified, strict quality control measures to guarantee your satisfaction.

-

Quality guaranteed. We'll make it right if a part is not made to spec.

-

Material certifications available

From CNC rapid prototyping to production

prototyping

With our experienced engineering staff and strong manufacturing skills, we are able to provide top-notch prototypes quickly. As a result, you may market products more swiftly and test prototype parts more quickly.

-

Obtain your quote within an hour.

-

quick shipping three business days

-

pricing is more competitive than that of our competitors.

production

For production orders,Our highly trained technical team will provide insightful design suggestions for your manufacturing parts, assuring workable solutions for your requirements.

-

guarantees superior precision and quality

-

Our skilled engineering team to offer valuable design recommendations

-

provide just-in-time delivery

Advantages of CNC Machining

CNC machining's subtractive process offers numerous advantages for both prototyping and production parts.

-

Precision and repeatability

-

Tolerances that are too tight, ±0.01mm

-

Production-grade materials

-

Within a day, quick-turn parts

-

Greater quantities at a lower piece-part price

-

Strong post-processing to improve cosmetics and material properties

Gallery of CNC surface machined parts

Cansda Machining can provide 10+ surface finishes. 60+ Materias Available<Aluminium, Steel, Polymers & More>

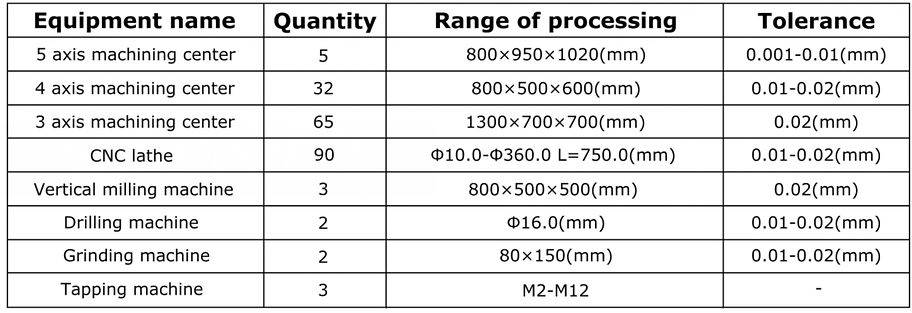

Our Equipment List

We Keep Top Notch Materials

Highest quality materials provide highest quality products

Plastic

POM (Delrin/Acetal)

Nylon

ABS

PEEK

Polycarbonate

Polyethylene

PVC

PMMA (Acrylic)

PET

Polypropylene

Metal

Aluminum

Stainless steel

Mild steel

Brass

Copper

Tool steel

Titanium

Inconel

Magnesium

Invar

Elastomer

EPM

EPDM rubber

Epichlorohydrin rubber (ECO)

Polyacrylic rubber (ACM, ABR)

Silicone rubber (SI, Q, VMQ)

Fluorosilicone rubber (FVMQ)

Fluoroelastomers (FKM, and FEPM)

Viton, Tecnoflon, Fluorel, Aflas

Magnesium

Perfluoroelastomers (FFKM)

Recent projects we finished

CERTIFICATES

The entire time I worked with CANSDA was excellent. They and I have been collaborating together for more than 7 years, and they never cease to impress me. Outstanding customer service and workmanship. I have referred Cansda to my friends and he is equally impressed. I highly recommend Cansda for your next project

Dave Ellyatt

_edited.jpg)

Chief Product Officer, ONI

I've been working with CANSDA for a while now. Production and delivery happened far faster than anticipated. The parts' quality has almost always been superb. I had a great experience working with Cansda Customer care would come first! To deliver your parts on time, Cansda works swiftly and closely with you. Also, the quotes get very fast just need a few hours.! It takes very little time,its a really valuable supplier.

_edited.jpg)

Ben Dersler

Purchasing manager, LPS

What a pleasure it was to work with CANSDA! I only wanted to do the prototyping at first because I was so tiny and wasn't expecting much, but I was thrilled when they returned my product exactly as I had intended! prompt and extremely affordable delivery. Customer service answer within an hour to any request with knowledge and respect for your work. I highly recommand it.

_edited.jpg)

Ryan Fry

Product Designer, Drolo

Using CANSDA for many years now. Always quick, always efficient, always reliable. Communication is excellent, they always deliver exactly when they promise, quality is outstanding,If something's wrong they redo the parts without any drama. Compared to most European CNC providers, Cansda‘s customer service is head and shoulders above. Highly recommended.

Remo Casadei

Product R&D DPT,

BYD

Take a Glance at What Our Customers Said

Our Amazing Clients

_PNG.png)

_PNG.png)

FAQ

-

Com quais materiais você trabalha?Somos especializados na usinagem de peças de vários metais, incluindo alumínio, latão, cobre, aço inoxidável e titânio. Também podemos trabalhar com alguns plásticos e outros materiais. Entre em contato conosco para discutir suas necessidades específicas de material.

-

Qual é o seu prazo de entrega para a fabricação de peças?Nosso prazo de entrega varia de acordo com a complexidade e quantidade das peças que você precisa. Normalmente, nosso tempo de resposta é de 7 dias úteis, mas podemos agilizar os pedidos por uma taxa adicional. Forneceremos uma estimativa de prazo de entrega mais precisa assim que analisarmos sua solicitação de cotação.

-

Você oferece algum serviço de acabamento para peças usinadas?Sim, oferecemos uma variedade de serviços de acabamento, incluindo anodização, revestimento em pó, pintura e polimento. Também podemos fornecer operações secundárias, como montagem, gravação a laser e gravação. Contacte-nos para mais informações.

-

Como você garante a qualidade dos seus produtos?Temos um rigoroso processo de controle de qualidade para garantir que todas as peças que fabricamos atendam ou excedam as expectativas de nossos clientes. Usamos equipamentos avançados de inspeção, como máquinas de medição por coordenadas (CMMs), para verificar a precisão dimensional e a consistência. Também contamos com uma equipe treinada de inspetores que realizam inspeções visuais e testes funcionais.

-

Como faço para enviar uma solicitação de cotação?Você pode enviar uma solicitação de cotação em nosso site, preenchendo o formulário em nossa página de contato ou enviando um e-mail diretamente para [info@cansdamachining.com]. Inclua o máximo de informações possível, incluindo desenhos ou especificações de peças, requisitos de material e quantidade desejada.

-

Que tipos de pagamentos você aceita?Aceitamos vários métodos de pagamento, incluindo transferências bancárias e PayPal. Também podemos definir condições de crédito para clientes qualificados. Contacte-nos para mais informações.

-

Você oferece frete internacional?Sim, podemos enviar nossas peças usinadas para praticamente qualquer local do mundo. Temos experiência em trabalhar com clientes internacionais e podemos fornecer opções de envio e custos com base na sua localização.

-

Qual é a sua política de devolução de peças defeituosas?Nós nos esforçamos para fabricar peças da mais alta qualidade e apoiamos nosso trabalho. Se você receber uma peça com defeito, entre em contato conosco imediatamente e trabalharemos com você para corrigir o problema. Podemos solicitar que você forneça fotos do defeito. Reservamo-nos o direito de determinar se uma peça está com defeito ou não. Se o problema for nossa culpa, garantimos o envio das peças refeitas em até 7 dias úteis

-

Como posso reduzir o custo das minhas peças usinadas?Existem várias maneiras de reduzir o custo de suas peças usinadas. Uma maneira é otimizar o projeto de sua peça para minimizar a quantidade de material e o tempo de usinagem necessários. Nossos engenheiros experientes podem fornecer feedback de projeto para ajudá-lo a obter economia de custos. Outra maneira é considerar o uso de um material diferente que pode ser mais econômico para sua aplicação. Além disso, encomendar peças em quantidades maiores pode levar a descontos por volume. Entre em contato conosco para discutir maneiras de reduzir o custo de suas peças usinadas sem comprometer a qualidade.

-

Que padrões de tolerância você garante?Temos uma vasta experiência trabalhando com tolerâncias rígidas e garantimos que todas as peças que fabricamos atenderão ou excederão as tolerâncias especificadas nos desenhos ou especificações das peças. Podemos trabalhar com tolerâncias tão apertadas quanto +/- (0,002 mm). Usamos equipamentos avançados de inspeção, como máquinas de medição por coordenadas (CMMs), para verificar a precisão dimensional e a consistência. Contamos também com uma equipe treinada de inspetores que realizam inspeções visuais e testes funcionais. Entre em contato conosco para discutir seus requisitos específicos de tolerância.

-

Como sei o estado de produção da minha encomenda?Entendemos a importância de manter nossos clientes informados sobre o status de seus pedidos. Quando recebermos seu pedido, forneceremos uma data estimada de conclusão. Também enviaremos atualizações regulares durante todo o processo de fabricação para mantê-lo informado sobre o progresso. Você pode entrar em contato conosco a qualquer momento para solicitar uma atualização sobre o status do seu pedido. Além disso, podemos fornecer informações de rastreamento assim que suas peças forem enviadas. alguns detalhes, por favor, verifique a imagem abaixo

-

What industries do you serve with your CNC machining services?Our CNC machining services cater to diverse industries, including aerospace, automotive, electronics, medical, defense, consumer products, and more. We have experience working on projects across various sectors and can meet specific industry standards and requirements

-

What is your pricing structure for CNC machining servicesOur pricing structure is based on factors such as material costs, machining complexity, order volume, and any additional services or finishes required. We provide transparent and competitive pricing, and we're happy to provide detailed quotes for your specific projects

-

Do you offer international shipping for machined parts?Yes, we offer international shipping for machined parts. We have experience with global logistics and can arrange shipping to your desired destination, ensuring timely delivery and secure handling of your parts.

-

What are your capabilities for complex geometries and intricate designs?Our CNC machining capabilities allow us to work with complex geometries, intricate designs, tight corners, and fine details. We leverage advanced machining techniques and high-precision tools to achieve the desired results.

-

What is your typical turnaround time for orders?Our turnaround time varies depending on factors such as part complexity, order size, and material availability. We strive to provide efficient and timely service, and we'll work closely with you to meet your project deadlines.

-

How do you ensure the quality of machined parts?We employ rigorous quality control measures throughout the manufacturing process. This includes in-process inspections, final inspections, and the use of advanced metrology equipment to verify dimensional accuracy and surface finish.

-

What tolerances can you achieve with CNC machining?Our CNC machining processes can achieve tight tolerances, typically ranging from +/- 0.005 inches to +/- 0.001 inches, depending on the material, geometry, and part size. We prioritize precision and quality in every project we undertake.

-

Can you handle both prototyping and production runs?Yes, we can handle both prototyping and production runs. Whether you need a single prototype or high-volume production, our flexible manufacturing capabilities allow us to accommodate a wide range of order sizes.

-

What materials can you work with using CNC machining?We specialize in machining a wide range of materials, including metals (such as aluminum, steel, stainless steel, brass, and titanium), plastics (such as ABS, acrylic, nylon, and polycarbonate), and various engineering-grade materials.

-

What file formats do you accept for part designs?We accept a variety of file formats, including STEP, IGES, STL, DXF, DWG, and more. Our team can work with your preferred design software and file formats to ensure seamless communication and accurate manufacturing.